Advanced K-Defense Mobility Technology Development through Drag Reduction

UWV Long-term Operation Research Lab

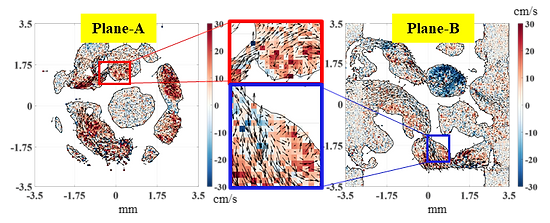

The Multiscale Heat & Fluid Flow Lab (MFL) is equipped with a Taylor-Couette flow experimental setup, enabling both friction drag measurements and velocity field analysis using 2D-PIV. In particular, the lab investigates drag reduction mechanisms by forming air layers (plastrons) on porous superhydrophobic surfaces. The system allows for pressurization, making it possible to analyze how changes in pressure affect the plastron and the resulting drag reduction. With growing military threats, there is an increasing emphasis on enhancing anti-submarine surveillance capabilities, highlighting the need for unmanned underwater vehicles (UUVs). Extending the operational duration of underwater vehicles has become a critical research focus. To this end, MFL is developing technologies to generate and retain microbubbles on superhydrophobic surfaces under high-pressure conditions found in deep-sea environments. This approach aims to reduce frictional drag and improve energy efficiency. This research is being conducted in collaboration with the UWV Long-Term Operation Research Lab (LORL) and the Agency for Defense Development (ADD).

Energy &

Environment

Future

Mobility

Publication

1.

Presentation Video

1.

2.

3.

4.

5.

6.

7.

8.

9.

Patent

1.

2.

S. Ahn, S. Jo, W. Song, H. Lee, G. Ku, M. Kim, D. Kim, S. Song, 2025, "Characteristics of turbulent Taylor-Couette flow of low-viscosity fluid on plastron-covered superhydrophobic surface", International Journal of Heat and Fluid Flow, 114, 109805

S. Ahn and S. Song "Development of Taylor-Couette flow apparatus and visualization of velocity fields", NCFE, 2020, August, 13, Jeju, Korea

S. Ahn, S. Song, "Development of PIV System and Preliminary Results for Taylor-Couette Flow", KSME Conference, 2021, Nov. 3, Gwangju, Korea

W. Song, S. Ahn, K. Pyo, S. Kim, J. Yoon, S. Song, "Evaluation on drag reduction of super hydrophobic surfaces using Taylor-Couette flow", KIMST, 2022, June. 10, Jeju, Korea

S. Ahn, W. Song, S. Song, "Measurement of friction drag and super water repellency surface flow visualization using Taylor-Couette flow", NCFE, 2022, June. 23, Changwon, Korea

W. Song, S. Ahn, K. Pyo, S. Kim, M. Kim, J. Park, D. Kim, S. Song, "Drag reduction by air layer on superhydrophobic surface in a Taylor-Couette flow", APS DFD, 2022, November. 20, Indianapolis, USA

W. Song, S. Ahn, K. Pyo, G. Ku, M. Kim, I. Jang, S. Song, "Flow Visualization of Superhydrophobic Surface Using PIV System in Taylor-Couette Flow", KSME, 2023, May. 18, Seoul, Korea

W. Song, S. Ahn, K. Pyo, G. Ku, M. Kim, S. Song, "(LORL)Drag Reduction of Superhydrophobic Surface using plastron in turbulent flow", KSME, 2023, November. 3, Incheon, Korea

S. Ahn, W. Song, K. Pyo, I. Jang, G. Ku, M. Kim, D, Kim, S. Song, "Drag Reduction of Superhydrophobic Surfaces Using Counter-rotating Taylor-Couette Facility", KSVI, 2023, November. 17, Gwangju, Korea

W. Song, H. Lee, G. Ku, M. Kim, D. Kim, S. Song, "Drag Reduction by Plastron on Superhydrophobic Surface in Turbulent Taylor-Couette Flow", KIMST, 2024, June.13, Jeju, Korea

Superhydrophobic Three-Layered Structures Film for Drag Reduction and Method of Fabricating the Same

Patent No. 10-1887075, Patent Registration Date : 2018.08.03

Superhydrophobic Porous Membrane Structure for Underwater Air Layer Holding

Patent No. 10-1974642, Patent Registration Date : 2019.04.25

UWV Long-term Operation Research Lab

Agency for Defense Development

Ministry of National Defense

Research Center & Sponsor

1.

2.

3.

Analysis of Heat Transfer in Hyperloop System

Flow Noise Research Center

As a next‑generation mode of transport, the Hyperloop is being actively developed by the Korea Railroad Research Institute (KRRI). In mechatronic systems that rely on electromagnets—such as those propelling a Hyperloop pod—thermal loads can strongly influence electrical performance. Because the magnets operate inside a near‑vacuum tube, mitigating heat in this extreme environment is critical.

The Multiscale Heat & Fluid Flow Laboratory (MFL), working with KRRI, investigated the system’s thermal behavior under design‑specific heat loads and devised cooling solutions to eliminate thermal bottlenecks. Computational‑fluid‑dynamics analyses quantified flow and cooling performance across key design parameters and confirmed the need for supplementary thermal management. Leveraging these insights, the team proposed both active and passive cooling concepts tailored to operational constraints and structural requirements.

Energy &

Environment

Future

Mobility

Research Presentation Video

1.

Research Center & Sponsor

1.

2.

Flow Noise Research Center

Korea Railroad Research Institute

International MRV Challenge Participation for Benchmarking Complex Flows

Collaborative Research

The Multiscale Heat & Fluid Flow Lab (MFL) has actively participated in a series of international MRV Challenges to evaluate the reliability and reproducibility of magnetic resonance velocimetry (MRV) in complex flow conditions.

These global initiatives involve multiple institutions conducting synchronized 4D flow MRI measurements on standardized geometries under shared flow conditions, allowing direct cross-laboratory comparisons despite differences in hardware and processing pipelines.

In the 2019 MRV Challenge, MFL used a 3.0T Philips scanner with 6-point phase-contrast encoding and divergence-free smoothing to capture turbulent flow through a U-bend geometry, successfully resolving primary and secondary flow features. In a subsequent challenge, MFL investigated pulsatile jet flow interacting with a cube array inside a square duct using phase-locked MRV, dividing the pulsatile cycle into 20 time-resolved phases with customized post-processing for distortion correction and wall-bounded flow accuracy.

Despite hardware and protocol variations across teams, all participants demonstrated highly consistent results, confirming the robustness of MRV in capturing complex unsteady and turbulent flow features. These efforts have included collaborations with Stanford University–USMA, the University of Rostock, University of Illinois Urbana-Champaign, Mayo Clinic, and Seoul National University, advancing the role of MRV in experimental fluid mechanics.

Energy &

Environment

Research Publication

1.

2.

Research Presentation Video

1.

2.

3.

4.

M. J. Benson, A. J. Banko, C. J. Elkins, D. An, S. Song, M. Bruschewski, S. Grundmann, D. D. Borup and J. K. Eaton, 2020, "The 2019 MRV challenge: turbulent flow through a U-bend". Experiments in Fluids, 61, 148

M. J. Benson, A. J. Banko, C. J. Elkins, D. An, S. Song, M. Bruschewski, S. Grundmann, T. Bandopadhyay, L. V. Roca, B. Sutton, K. Han, W. Hwang and J. K. Eaton, 2023, "MRV challenge 2: phase locked turbulent measurements in a roughness array", Experiments in Fluids, 64, 28

D. An, S. Song, C. Im and S. Oh, "MRV Flow Visualization of U-bend Using 3T and 7T MRI and Comparison of Results", KSVI, 2019, December. 6, Daegu, Korea

D.G. An, S. Song, "Magnetic Resonance Velocimetry for a Pulsatile Cross-Jet Flow Measurements in Building Structures (2021 MRV Challenge)", KSME Fluid Engineering Division Spring Conference, 2021, Aug. 18, (Online)D.G. An, S. Song, "2021 MRV Challenge: Hanyang University Results", 74th APSDFD, 2021, November. 22, Arizona, USA

H. Dong, S. Song, "Visualization of Turbulent Kinetic Energy Using Magnetic Resonance Velocimetry on Cross Jet Flow", APS DFD, 2023, November. 20, Washington DC, USA

Research Center & Sponsor

1.

National Research Foundation

Comparison of compressor flow performance and pressure drop based on MRV

LG Electronics - Hanyang University Smart Appliance Center

Flow Noise Research Center

The Multiscale Heat & Fluid Flow Lab (MFL) applies MRV-based techniques to characterize three-dimensional flow and turbulence structures in suction mufflers, with the goal of comparing flow performance and pressure drop. Two 2:1 scaled models of the suction muffler, including the compressor shell, were fabricated via stereolithography 3D printing. The three-dimensional mean velocity and turbulent kinetic energy (TKE) fields were measured to provide a comprehensive description of the internal flow characteristics, and the omni-directional integration (ODI) method was employed to estimate the internal pressure distribution in the primary flow regions of the suction muffler. The results showed that the pressure drop at the outlet plane in Model 2 was reduced by approximately 44.4% compared to Model 1. Significant flow non-uniformity at both the inlet and outlet, as well as flow separation, recirculation, and high TKE regions within both suction muffler models were identified. These findings provide valuable insights into the complex flow behavior within suction mufflers, establish boundary conditions and experimental benchmarks for validating Reynolds-Averaged Navier-Stokes (RANS) turbulence models, and highlight the potential of MRV measurements for investigating, understanding, and improving the flow performance of suction mufflers. This research is being conducted in collaboration with the Vibration Noise Project at the H&A R&D Center of LG Electronics.

Energy &

Environment

Research Center & Sponsor

1.

2.

3.

LG Electronics - Hanyang University Smart Appliance Center

LG Electronics

Flow Noise Research Center

Improving flow performance in a heat pump tumble dryer using MRV

LG Electronics - Hanyang University Smart Appliance Center

Flow Noise Research Center

The Multiscale Heat & Fluid Flow Lab (MFL) applies MRV-based techniques to characterize three-dimensional flow and turbulence structures in a heat pump tumble dryer, with the goal of reducing flow-induced noise and enhancing energy efficiency. Scaled-down models of the machine room and rear duct were fabricated using stereolithography 3D printing, and the 3D mean velocity and turbulent kinetic energy (TKE) fields were measured. Results from the reference model showed highly non-uniform flow distribution, high TKE regions, and a high backflow ratio at the perforated plate, which may have contributed to lint accumulation. The structural modifications resulted in a reduction of over 50% in high-TKE regions within the machine room, along with improved flow uniformity and a noticeable decrease in secondary flow intensity. In the rear duct, high-TKE regions were reduced by more than 80%, and the backflow ratio at the perforated plate decreased by over 54%, which is considered a key factor contributing to the suppression of lint accumulation in the rear duct region. These findings offer valuable insights into the complex flow behavior of heat pump tumble dryers, and demonstrate the potential of MRV as a powerful tool for investigating, understanding, and optimizing the flow performance of household appliances. This research is being conducted in collaboration with the Vibration Noise Project at the H&A R&D Center of LG Electronics.

Energy &

Environment

Research Center & Sponsor

1.

2.

3.

LG Electronics - Hanyang University Smart Appliance Center

LG Electronics

Flow Noise Research Center

Study on the Correlation Between Interior Pressure and Wind Noise in SUVs

Flow Noise Research Center

The Multiscale Heat & Fluid Flow Lab (MFL) is conducting advanced research on airflow dynamics within SUV cabins, focusing on the performance of extractor systems. Flow visualization technique called MRV(Magnetic Resonance Velocimetry) is utilized to analyze the velocity field surrounding the Extractor Grill outlet of SUVs, aiming to enhance air exhaust efficiency and reduce internal pressure. This research examines how pressure differences between the interior and exterior contribute to tonal noise, such as whistle sounds, during high-speed driving. To address this, the lab is developing optimized outlet geometries that mitigate pressure differences and improve flow characteristics at the extractor outlet. Moreover, MFL is investigating the correlation between outlet flow structures and pressure-driven tonal noise across different vehicle architectures to establish a universal SUV design framework. This research is being pursued in collaboration with the Acoustics and Vibration Lab(AVL) and is HYUNDAI NGV.

Energy &

Environment

Future

Mobility

Flow Noise Research Center

HYUNDAI NGV

Research Center & Sponsor

1.

2.

Development of Pressurized Water Tunnel

UWV Long-term Operation Research Lab

The Multiscale Heat & Fluid Flow Lab (MFL) has developed a pressurized water tunnel to replicate the high hydrostatic pressure environments experienced by underwater vehicles such as submarines. This facility enables visualization of the air layer (plastron) formed on superhydrophobic surfaces (SHS) under pressurized flow conditions using a high-resolution camera system. The study focuses on maintaining and regenerating the plastron through electrolysis, even under elevated pressures and Reynolds numbers. Hue-based image analysis is employed to quantitatively assess the persistence of the plastron layer. With the increasing importance of anti-submarine surveillance in modern defense, there is growing demand for long-endurance unmanned underwater vehicles (UUVs). Extending operational duration is a key challenge, and MFL addresses this by developing techniques to generate and sustain microbubbles on SHS under deep-sea pressure conditions. This approach aims to reduce skin-friction drag and enhance energy efficiency. This research is being conducted in collaboration with the UWV Long-Term Operation Research Lab (LORL) and the Agency for Defense Development (ADD).

Energy &

Environment

Future

Mobility

Research Presentation Video

1.

UWV Long-term Operation Research Lab

Agency for Defense Development

Ministry of National Defense

Research Center & Sponsor

1.

2.

3.

Flow Field Analysis and Design Optimization of LG Hair Dryer Using PIV and MRV

LG Electronics - Hanyang University Smart Appliance Center

Flow Noise Research Center

The objective of this research is to enhance the aerodynamic performance and user experience of next-generation premium hair dryers by visualizing and optimizing both internal and external flow fields. Specifically, the study aims to strengthen the Coanda effect by improving the external geometry, thereby increasing airflow concentration and efficiency. Additionally, it seeks to reduce operational noise by refining the internal structure based on a thorough analysis of the internal flow. To achieve these goals, external flow is visualized using Particle Image Velocimetry (PIV), which captures high-resolution velocity fields and assesses the formation of the Coanda effect. Internal flow is examined through Magnetic Resonance Velocimetry (MRV), allowing for non-invasive, three-dimensional visualization of the complex internal flow structures. The ultimate goal of the research is to provide engineering insights that can inform the aerodynamic design and noise reduction strategies necessary for developing high-performance hair dryers. This research is conducted at the Experimental Fluid Dynamics Laboratory (EFD Lab) at Hanyang University and is supported by an industry-academic collaboration with LG Electronics.

Energy &

Environment

Research Center & Sponsor

1.

2.

3.

LG Electronics - Hanyang University Smart Appliance Center

LG Electronics

Flow Noise Research Center

Pore-scale Flow Visualization and Reactive Transport Analysis for CO2 Mineralization in Basalt

STEAM (Science, Technology, Engineering, Arts, Mathematics) Project

This project focuses on leveraging basalt formations as a stable solution for long-term carbon sequestration through CO₂ mineralization. To optimize this process, it is crucial to understand the pore-scale flow dynamics and the chemical reactions that occur within the rock structure. The primary objective is to visualize three-dimensional fluid flow in basalt analogs and investigate how mineralization processes alter the pore geometry and affect fluid transport behavior. Additionally, the project aims to produce high-resolution experimental data that can be used to validate and refine field-scale predictive models.

To achieve these goals, the research employs Magnetic Resonance Velocimetry (MRV) and micro-CT imaging. These advanced imaging techniques are applied to custom-fabricated rock-on-a-chip systems that simulate natural porous basalt. Through these tools, the project can capture detailed insights into fluid movement and reactive transport, allowing direct observation of how pore structures evolve before and after CO₂ or hydrogen injection under various flow conditions.

Energy &

Environment

Research Center & Sponsor

1.

Ministry of Science and ICT

Visualization of Multi phase Flow Inside a Dishwasher Using MRV

LG Electronics - Hanyang University Smart Appliance Center

Flow Noise Research Center

At the Multiscale Heat and Fluid Flow Lab (MFL), we have conducted a range of single-phase flow studies using Magnetic Resonance Velocimetry (MRV), including velocity field analysis and flow noise reduction based on turbulent kinetic energy.

However, because MRI detects signals from hydrogen nuclei, multiphase flows involving air have rarely been explored using MRV.

To address this limitation, MFL is conducting research that leverages MR signals from air bubbles—previously considered noise—for multiphase flow analysis.

In particular, we visualize the multiphase flow around a filter inside a dishwasher—an everyday example of multiphase flow—and analyze the flow characteristics to propose strategies for improving the filtration performance of the built-in filter.

This research is being carried out in collaboration with LG Electronics.

Energy &

Environment

Research Center & Sponsor

1.

2.

3.

LG Electronics - Hanyang University Smart Appliance Center

LG Electronics

Flow Noise Research Center

.png)

.png)